The Ultimate Comparison of Packaging Machines Efficiency and Cost Effectiveness in Modern Production

In the dynamic landscape of modern production, the efficiency and cost-effectiveness of packaging machines have emerged as critical determinants of operational success. According to a report by MarketsandMarkets, the global packaging machinery market is projected to grow from $40.2 billion in 2020 to $53.2 billion by 2025, highlighting a compound annual growth rate (CAGR) of 5.8%. This growth underscores a pivotal shift toward automation and advanced technology in packaging, where businesses are increasingly investing in high-performance machines that reduce waste and enhance throughput.

Furthermore, a study by the International Packaging Association indicates that companies implementing state-of-the-art packaging solutions can achieve up to 30% improvements in productivity. In this blog, we will dive into the ultimate comparison of packaging machines, exploring both their efficiency metrics and cost implications to equip manufacturers with the insights they need to thrive in a competitive market.

Efficiency Metrics: Key Performance Indicators for Packaging Machines

When assessing the efficiency of packaging machines in modern production, it is crucial to focus on key performance indicators (KPIs) that directly impact operations. Metrics such as output rate, downtime, and changeover time provide valuable insights into a machine's efficiency. An optimal output rate ensures that production targets are met consistently, while minimizing downtime prevents costly interruptions. Additionally, evaluating changeover time is essential for facilities that work with multiple products, as quicker transitions can significantly enhance overall productivity.

Tip: Regularly monitor these efficiency metrics in real-time to identify patterns and areas for improvement. Implementing a simple dashboard system can help streamline this process, offering immediate visibility into machine performance.

Another important KPI to consider is the rate of defective packages produced. High defect rates not only waste materials but also negatively impact customer satisfaction. Conducting routine quality checks can aid in identifying and correcting causes of defects, contributing to a more cost-effective production process.

Tip: Invest in advanced monitoring technology to track defect rates automatically. This proactive approach allows for immediate adjustments and can lead to substantial long-term savings.

Cost Analysis: Comparing Initial Investment vs. Long-term Savings

When evaluating packaging machines for modern production lines, cost analysis becomes a crucial factor in the decision-making process. The initial investment in high-quality packaging machinery can often be substantial, leading many businesses to weigh the immediate financial implications against potential long-term savings. It's essential to consider not only the upfront costs but also the ongoing operational expenses, such as maintenance, workforce requirements, and energy consumption.

Long-term savings can stem from enhanced efficiency and reduced waste, which high-performance machines typically provide. Investing in advanced technology can lead to faster production rates and improved product integrity, translating into fewer returns and higher customer satisfaction. Furthermore, as manufacturers optimize their packaging processes, they may discover reduced labor costs and lower operational downtime, which ultimately contribute to a more favorable return on investment. Balancing these initial costs with the promise of long-term benefits is key to making an informed decision that aligns with the financial goals of any production facility.

Technology Advancements: Impact on Packaging Machine Efficiency Rates

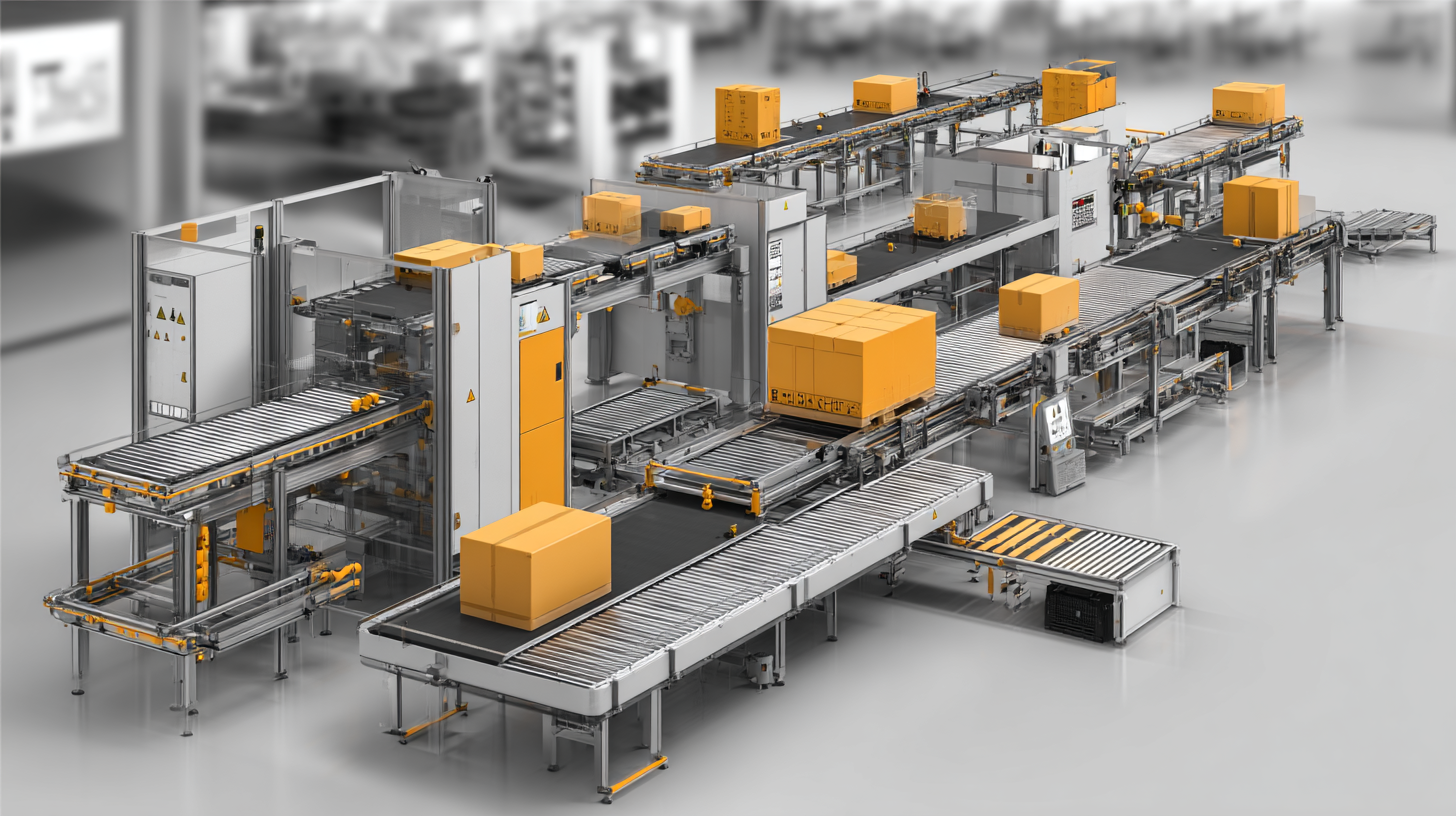

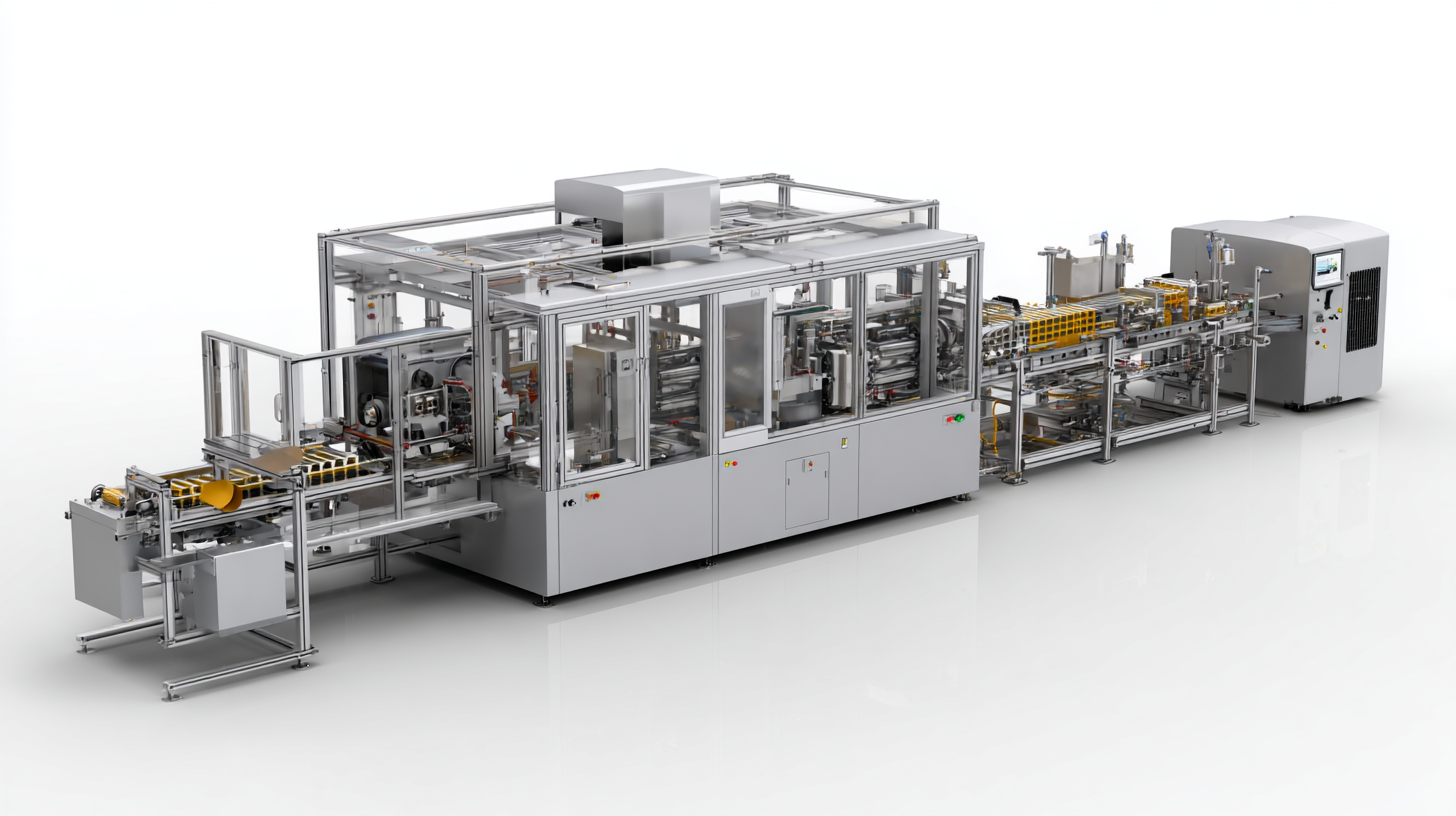

Recent advancements in technology have significantly transformed the landscape of packaging machines, leading to remarkable enhancements in efficiency rates. Cutting-edge innovations, such as automation and artificial intelligence, are now integrated into packaging processes, allowing machines to operate at unprecedented speeds while maintaining precision. Smart sensors and real-time monitoring systems enable manufacturers to optimize production lines, reducing downtime and minimizing waste. These technological improvements not only streamline operations but also contribute to higher output and lower operational costs.

Moreover, the impact of technology extends beyond mere speed; it also improves the versatility of packaging machines. Modern equipment is now capable of handling a wider range of products, accommodating various package sizes, and adapting to specific market demands with ease. This flexibility allows businesses to respond quickly to consumer trends without significant capital investment in new machinery. As the packaging industry continues to evolve, leveraging advanced technologies will be crucial for companies aiming to enhance their productivity and remain competitive in an increasingly dynamic market.

Industry Standards: Benchmarking Costs Across Different Packaging Solutions

In the ever-evolving landscape of modern production, understanding the costs associated with various packaging solutions is crucial for manufacturers looking to enhance efficiency. According to a recent report by PMMI, the Association for Packaging and Processing Technologies, nearly 40% of manufacturers are prioritizing cost reduction in their purchasing decisions, highlighting the need for effective benchmarking against industry standards. By assessing different types of packaging machines, organizations can identify optimal solutions that balance cost with performance.

When evaluating packaging options, it’s essential to consider not only the initial investment but also the long-term operational costs. Reports suggest that automated packaging solutions can reduce labor costs by up to 30% while improving throughput rates by nearly 50%. In today’s competitive market, making informed comparisons can lead to better budget allocations and enhanced profitability.

Tips: Always analyze the total cost of ownership (TCO) when selecting a packaging machine. Look beyond purchase price to include maintenance, energy consumption, and potential downtime costs. Additionally, engage with suppliers to obtain detailed operational data to better inform your benchmarking process and achieve optimal cost-effectiveness in your production line.

Case Studies: Real-world Examples of Efficiency Challenges in Production Lines

In the fast-paced world of modern production, efficiency challenges often arise that can significantly impact the bottom line. Case studies from various industries reveal that even the most advanced packaging machines can face hurdles that hinder performance. For instance, a beverage manufacturer recently struggled with a bottling line where inconsistencies in packaging materials led to frequent machine downtimes. By analyzing these inefficiencies, the company was able to implement targeted upgrades, resulting in a 20% increase in production speed and a substantial reduction in material waste.

Another notable example comes from the pharmaceutical sector, where precision is paramount. A leading pharmaceutical company encountered issues with their packaging process due to an outdated labeling system that caused errors during product identification. By investing in state-of-the-art labeling machines, they not only improved accuracy but also enhanced the overall workflow. This transition highlighted the vital importance of staying current with technology, as it directly contributes to cost-effectiveness and operational efficiency. Through these real-world examples, the significance of addressing efficiency challenges in production lines becomes clear, demonstrating that strategic investments can lead to remarkable returns.

The Ultimate Comparison of Packaging Machines Efficiency and Cost Effectiveness in Modern Production

| Machine Type | Efficiency (%) | Cost ($) | Production Speed (units/hour) | Maintenance Frequency (per month) |

|---|---|---|---|---|

| Vertical Form Fill Seal | 85 | 15,000 | 200 | 2 |

| Horizontal Flow Wrapper | 90 | 20,000 | 180 | 3 |

| Labeling Machine | 95 | 10,000 | 350 | 1 |

| Shrink Wrapper | 88 | 12,500 | 150 | 4 |

| Case Packing Machine | 80 | 25,000 | 120 | 2 |