Ultimate Resource for Sourcing the Best Heat Sealing Machines Worldwide

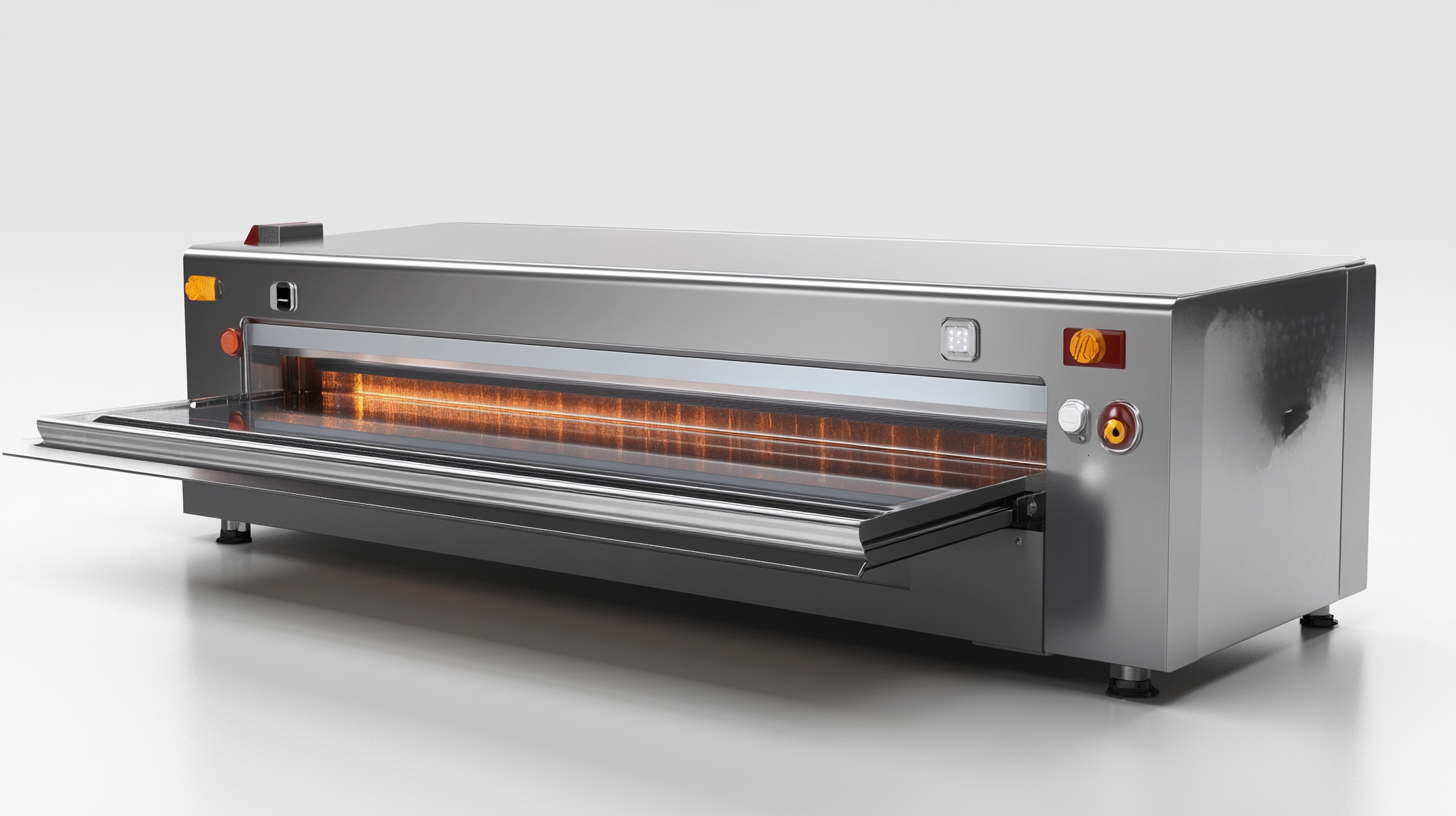

In today's fast-paced manufacturing world, efficiency and reliability are paramount, and one crucial piece of equipment that plays a significant role in achieving these goals is the heat sealing machine. These machines are essential for ensuring that products are securely packaged, maintaining freshness, and preventing contamination. As industries continue to evolve, the demand for high-quality heat sealing machines has surged, making it imperative for businesses to access the best resources available globally. This blog aims to be the ultimate guide for sourcing the most effective heat sealing machines, tailored to meet the diverse needs of various sectors, from food packaging to electronics.

Navigating the marketplace for heat sealing machines can be overwhelming, especially given the myriad of options available. Different models come with various features, specifications, and price ranges, which can make decision-making complex. In this blog, we will explore the key factors to consider when sourcing these machines, highlight leading manufacturers, and provide valuable insights into the latest advancements in technology. Whether you are a small business owner or part of a large corporation, our comprehensive resource will equip you with the knowledge needed to choose the perfect heat sealing machine for your operations.

Key Features to Look for in High-Quality Heat Sealing Machines

When sourcing high-quality heat sealing machines, there are several key features that should be at the forefront of your evaluation. First and foremost, the type of seal created is crucial. A machine that offers adjustable temperature settings and varying sealing speeds can significantly enhance usability and versatility. Whether you’re working with thin plastic films or thicker materials, a good heat sealing machine should adapt to different specifications, ensuring reliable and consistent seals. Another essential aspect is machine durability. Look for models made with robust materials that can withstand continuous operation. Stainless steel construction, for example, not only adds longevity but also facilitates easier cleaning and maintenance. Additionally, consider machines equipped with safety features, such as automatic shut-off and temperature control systems, to minimize the risk of overheating and ensure safe operation in any work environment. Moreover, ease of use plays a significant role when selecting a heat sealing machine. Intuitive controls and clear interfaces can reduce the learning curve for new operators, leading to increased productivity. Machines with adjustable height and angle settings can also enhance user comfort, making them suitable for a variety of tasks and workspaces. Ultimately, investing time in selecting the right machine with these key features can lead to increased efficiency and superior sealing quality in your production line.

Top Global Manufacturers of Heat Sealing Machines You Can Trust

When it comes to heat sealing machines, the market is rich with options, yet finding reliable manufacturers can be daunting. According to the latest report by Grand View Research, the global packaging market is expected to reach USD 1.2 trillion by 2025, with heat sealing machines playing a critical role in this growth. Leading manufacturers are stepping up their game to meet the rising demand for efficient and reliable sealing solutions.

Among the top global manufacturers is Bosch Packaging Technology, renowned for its innovative designs and sustainable practices. Their commitment to using energy-efficient technologies aligns with industry trends emphasizing eco-friendly production. Moreover, their extensive portfolio covers a wide range of applications from food packaging to pharmaceuticals, ensuring that they cater to diverse market needs.

Another trusted name is Sealed Air Corporation, recognized for its advanced heat sealing technology that enhances product shelf life. Their machines are designed for high-speed production, addressing the needs of fast-paced packaging environments. According to a report by MarketsandMarkets, the heat sealing machine market is expected to grow significantly, driven by advancements in technology and increased demand for packaged goods.

Finally, you can't overlook the reliable products from Multivac, a key player known for its state-of-the-art solutions that combine versatility with high performance. They provide comprehensive support and tailor solutions based on customer requirements, further solidifying their reputation in the industry. Trusting these established manufacturers can ensure you are investing in high-quality heat sealing machinery that meets the demands of modern-day packaging operations.

Comparative Analysis of Different Types of Heat Sealing Technologies

When selecting the right heat sealing technology for your packaging needs, understanding the various types available is crucial. Heat sealing machines utilize heat and pressure to bond materials, and their efficacy can significantly influence product integrity and shelf life. The two primary types of heat sealing technologies are impulse sealing and continuous sealing.

Impulse sealing operates by applying heat only during the sealing cycle, resulting in less energy consumption. This method is ideal for lower volume production, as it heats up quickly and offers precision in sealing various materials, from plastics to aluminum foils. However, it may not be suitable for high-speed production lines, where continuous sealing becomes advantageous. Continuous heat sealing machines maintain constant heat, allowing for a seamless workflow ideal for high-output environments. They are particularly effective for applications requiring long strips of packaging, as they can handle higher speeds while ensuring uniform seals.

Moreover, advancements in technology have led to the emergence of automated heat sealing systems that incorporate sensors and automation for greater efficiency. These systems not only enhance precision but also reduce the risk of human error in the sealing process. As companies continue to innovate in packaging solutions, understanding the strengths and weaknesses of each heat sealing technology will enable businesses to choose the best machine for their specific requirements, ultimately improving productivity and product quality.

Cost-Effectiveness: Budgeting for the Best Heat Sealing Solutions

In sourcing the best heat sealing machines worldwide, cost-effectiveness should be a primary consideration. As industries strive to optimize their processes and budgets, evaluating your investment in heat sealing solutions becomes essential. A thorough understanding of your budget will help you identify machines that not only meet your operational needs but also fit within your financial constraints.

Recently, many institutions have faced budget scrutiny, similar to the 2025 budget announcements from various educational bodies in China and the debates surrounding special budget proposals in Taiwan. These instances highlight the importance of careful budget planning and allocation. When it comes to heat sealing machinery, businesses should consider not only the upfront costs but also the long-term return on investment. Assessing factors such as durability, efficiency, and maintenance costs can lead to more informed decisions.

Furthermore, the ongoing fiscal evaluations in Australia emphasize the need for organizations to prioritize cost-effective solutions in their purchasing strategies. By exploring diverse price points and technological options in heat sealing machines, manufacturers can ensure they are making prudent investments that enhance productivity while keeping expenditures manageable. As you look into potential machines, remember that a well-planned budget is your best ally in sourcing equipment that offers both quality and value.

Essential Maintenance Tips to Extend the Lifespan of Your Heat Sealing Machine

Maintaining your heat sealing machine is crucial for ensuring its longevity and optimal performance. Regular maintenance not only extends the lifespan of the equipment but also enhances its efficiency, ensuring that you achieve consistent sealing quality. One of the primary maintenance tips is to keep the machine clean. Residue from previous sealing operations can accumulate over time, leading to inconsistent performance. Make it a habit to regularly clean the sealing surfaces and remove any debris that might affect the sealing process.

Another essential maintenance practice is to inspect and calibrate the machine periodically. Check the temperature settings and make sure that the heat elements are functioning correctly. Regularly testing the machine's sealing strength can also help identify any issues before they escalate into major problems. Additionally, lubricating moving parts can reduce friction and wear, helping the machine to operate smoothly and efficiently. Adhering to a maintenance schedule will not only help you prevent unexpected breakdowns but will also ensure that your heat sealing machine remains a reliable asset in your production line.

Lastly, always refer to the manufacturer’s guidelines for specific maintenance procedures tailored to your particular machine model. Keeping track of maintenance logs will also assist in identifying patterns that might indicate underlying issues. A proactive approach to maintenance can lead to significant savings in repair costs and downtime, ultimately enhancing your operation's productivity.