Exploring Innovative Options for Advanced Packaging Equipment Solutions

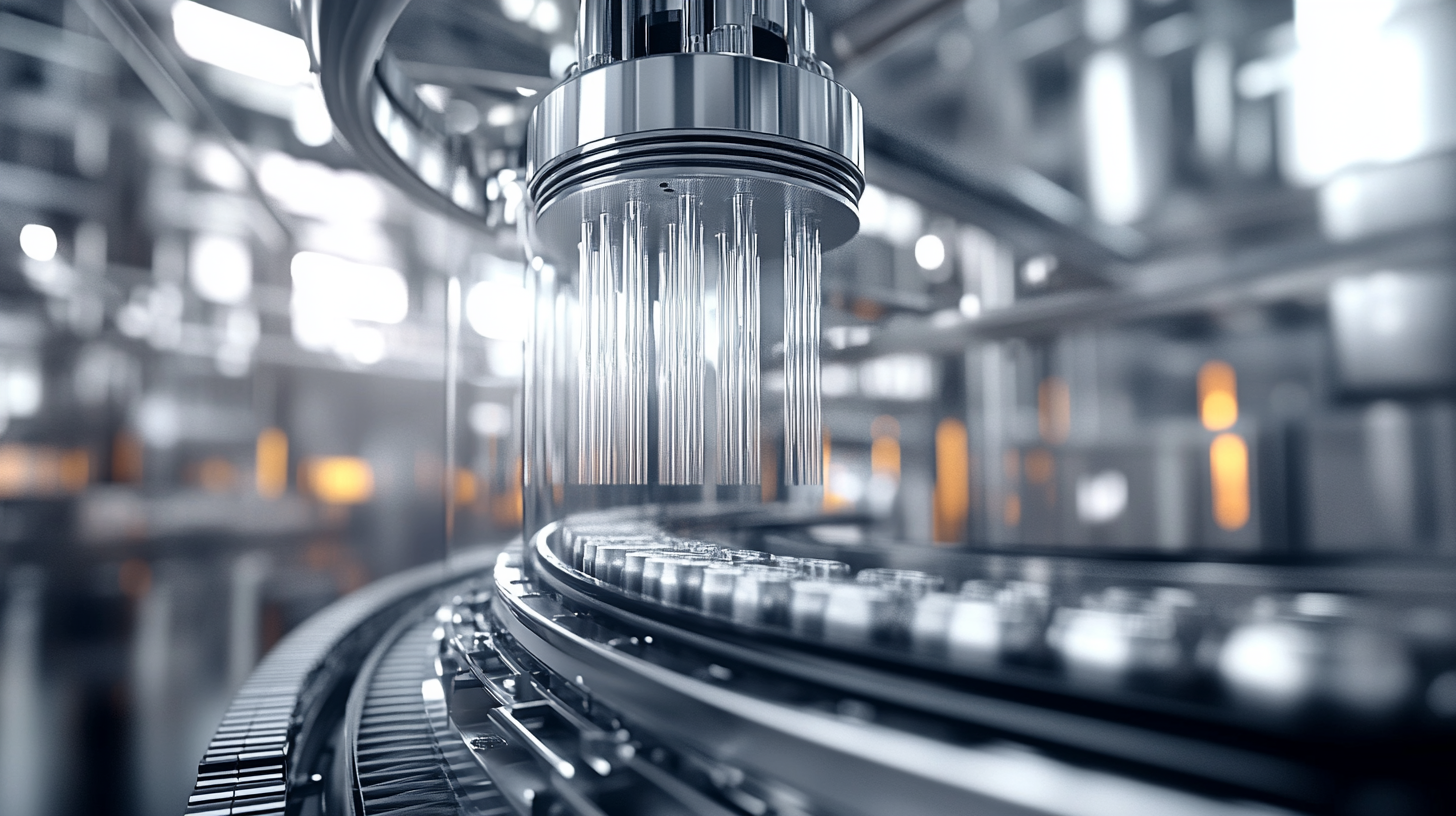

The need for innovative packaging machinery solutions assumes the highest degree of priority in today's fast-changing market. As companies try to become more efficient with operations and meet consumer expectations, the need to evaluate modern packaging machinery becomes essential. The objective of this blog is to explore the most recent trends and technologies transforming the packaging value chain in order to keep companies competitive and responsive amid a changing environment.

The integration of state-of-the-art features such as automation, sustainability, and digitalization is changing the design and operation of packaging machines. By reviewing different innovative techniques, organizations can pinpoint the best ways through which to reduce costs and environmental burden in their packaging operations. Let us follow through these innovations that not only enhance the packaging machine functionalities, but also provide a stepping stone toward a cleaner and more sustainable tomorrow for the industry.

Emerging Trends in Advanced Packaging Technologies

Some emerging currents in high-end packaging technologies within the packaging industry do not follow the traditional path and are evolving into the future of equipment solutions. One notable advancement of the future is the making of packaging systems by integrating them with smart technology or enhancing it with the use of sensors with the Internet of Things (IoT). That is to say, the real-time condition monitoring of the product can be made possible through the entire supply chain. With enhanced traceability, manufacturers' quality control also yields waste elimination and more operational efficiency. Another major trend has been advancing beyond sustainable packaging. More and more companies are making efforts to shrink their impact on the environment. They look up to innovations such as biodegradable materials, reusable packing systems, and energy-efficient equipment. Advanced packaging offerings are not only regulatory-fit but are also appealing to green-minded consumers; thus, sustainability becomes a major area of product development. Automation is also being integrated into the system packaging solution to become even more flexible at a faster rate of production. The automated system can switch to product sizes and formats without consuming a significant amount of time, which is important with respect to a fast-paced market. Such advancements in packaging systems not only improve the experience of production but also open up new efficient labor experiences and, therefore, smarter manufacturing processes by which changing consumer needs can be accommodated. Emerging trends in advanced packaging technologies are altogether the future of the sector with respect to innovation, sustainability, and efficiency-in other words, packaging solutions are going to continue to advance, graduate increasingly and respond to the needs of the market as all companies get increasingly committed to these endeavors.

Benefits of Investing in Innovative Packaging Solutions

Innovative packaging investment is beneficial not only because of its cost savings but also in many other areas besides. In the fast-changing market, many companies are now embedding their focus on sustainability for both their practices and materials as a result of consumer demand and regulatory pressures. For example, dairies and ready-to-eat food packaging are undergoing considerable transformations for more eco-friendly designs, including recyclability and biodegradability. This change demands that businesses invest in future-forward packaging equipment as changes meet market trends and not simply meet them.

Global statistics spell out exactly how sustainable packaging catches the trend. The reusable packaging market is set to reach a compound annual growth rate of 6.1% from 2024 to 2032 as regulatory backing for sustainable practices grows. Another example is the sustainable plastics market where businesses are meant to innovate towards minimizing environmental impacts and thus make big gains. There is no doubt that investments in these modern packaging technologies will enhance the convenience and sustainability demands of consumers while also giving a good edge to companies in an increasingly competitive market.

With companies like Sealed Air jumping straight into the rebranding process, innovation in packaging increasingly receives an even clearer focus definition. Such eco-innovations, complemented by technological advancements, will ensure that long-term futures are secured in a market that prefers an ecological view. It takes care of Mother Earth and helps to enhance brand loyalty to consumers who would love to consume eco-friendly products.

Key Features to Look for in Modern Packaging Equipment

Modern packaging equipment, at the forefront of creating efficiencies and sustainable practices across an array of industries, remains at the hub of packaging technology change. When looking at innovation in advanced packaging solutions for consideration, focus must be placed on features that enhance operational efficiency and product integrity. Smithers Pira recently reported that demand for automated packaging solutions is projected to grow annually at 5%, thus confirming that the industry is transitioning to ever-more-efficient and cost-effective methods of operation.

The most important feature to demand in any modern packaging equipment today is automation. Equipment incorporating robotics and artificial intelligence can streamline production processes, thereby reducing labor costs and human errors to a minimum. McKinsey has even found that an increase in packaging line productivity of approximately 30% is achievable through automation. This is thus considered a highly opportunistic time for companies to scale up their operations while maintaining high quality.

Another major issue when selecting packaging equipment is flexibility and adaptability. Handling an assortment of package sizes and materials can quickly become a fast-paced market with consumer preferences that change by the hour and thus are a large factor in downtime impact. According to PMMI, 70% of decision-makers in packaging consider easy product line switching an important feature when investing in machinery; thereby ensuring maximum returns on investment with minimized waste.

Another emerging trend is putting increasing pressure on manufacturers of modern packaging equipment: sustainability features. The equipment will, therefore, satisfy eco-friendly processing and materials requirements and appeal to consumers with environmentally friendly attitudes. The Euromonitor report states that 54% of global consumers would pay more for sustainable packaging- an essential criterion considered in the design of advanced packaging solutions.

Sustainability Considerations in Advanced Packaging Design

As the packaging industry evolves, the need for sustainable systems has become a crescendo for advanced packaging design. The recent report by Smithers called "The Future of Sustainable Packaging to 2025" stated that the sustainable packaging market would skyrocket to $1 trillion by around 2024. The surge in demand is mainly driven by increasing consumer demand for environment-friendly options and relatively stricter laws on plastic usage. Business is now looking into materials that address waste reduction and create better recyclability, such as biodegradable films and paper-based solutions.

Novel equipment for packaging is fundamental in ensuring that sustainability goals are achieved. These automated systems with machine learning and Internet of Things technologies help to optimize the usage of material while reducing wastage through production. According to a PMMI report, smart packaging solutions might reduce material costs by 30 percent. Furthermore, advancements in flexo and other printing processes open the way for the use of green inks and processes that lessen the carbon footprint of packaging solutions.

Moreover, integrating sustainability into packaging design greatly impacts brand loyalty. Statistics show that 65 percent of consumers are more inclined to purchase products from brands that exhibit sustainable practices. Such changing consumer behavior makes sustainability a priority for manufacturers, who then, in turn, invest heavily in advanced packaging systems that appeal to eco-conscious shoppers and facilitate the company's way of achieving ambitious environmental commitments. As manufacturers continue to business in the area, the comprehensive benefits of pursuing sustainability will trickle down through the larger packaging supply chain.

Case Studies: Successful Implementations of Advanced Packaging Solutions

In the fast-changing sphere of packaging technologies, new solutions form the basis around which challenges with regards to efficiency and sustainability can be resolved. Exemplary case studies present cases where advanced equipment and packaging have made full use of up-to-the-minute technologies. For instance, the change whereby operations and maintenance management have been enhanced by the integration of digital twins demonstrates a major shift in this space toward predictive maintenance and operational readiness and provides for real-time simulation and monitoring with improved decision-making and reduced downtime.

Companies that embrace advanced packaging strategies experience an average of 20% reduction in operational costs while boosting production by 30% compared to their base. Among the others, it is the incorporation of Building Information Modeling (BIM) in maintenance management that reflects a major step forward in allocating resources as well as improving collaboration among stakeholders. It is an example of how visual data representations can optimize workflows and streamline processes, allowing packaging operations to be dynamic and responsive to market needs.

The market for global packaging machinery is expected to grow to $50 billion by 2025, thanks to various innovations in automation and smart technology. Such advancements will empower manufacturers to provide customized packaging solutions that not only comply with regulations but also meet consumer preferences on sustainability. Presenting case studies of successful organizations implementing these solutions would show the actual benefits of adopting innovative technologies about packaging, thus earning a competitive edge in the market.