Understanding Global Standards for Importing Packaging Machinery Step by Step Guide

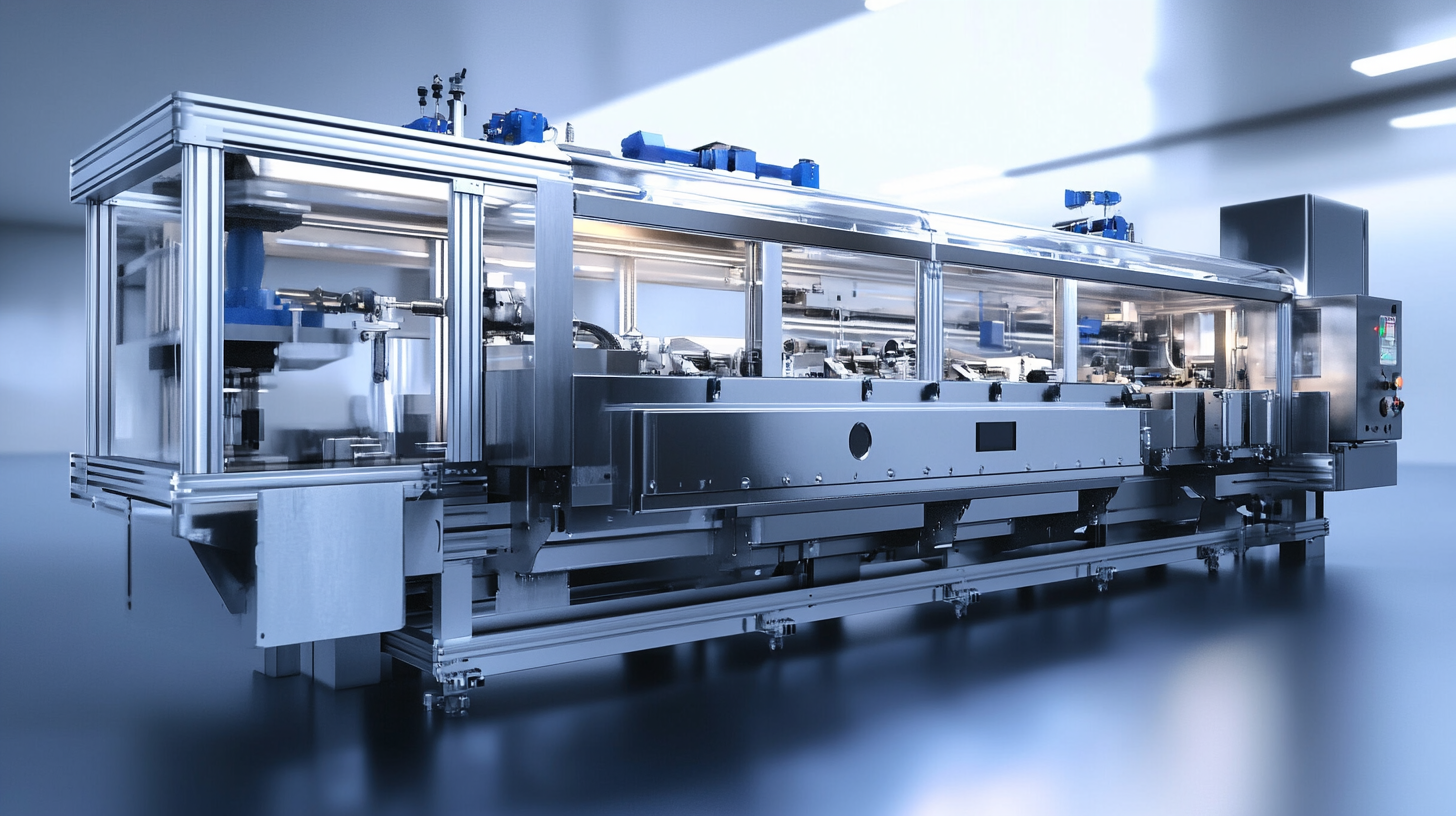

Navigating the global standards for importing packaging machinery can be a nightmare for most businesses and manufacturers. With international trade becoming more popular and the demand for efficient and innovative packaging solutions heightening, understanding these standards becomes crucial for compliance and operational excellence. The step-by-step guide aims to eliminate some of the mystery surrounding international shipping of packaging machinery by allowing coverage of various regulations imposed on machinery by different countries and certifications and safety requirements.

The importance of conforming to international standards for packaging machines is highlighted as companies endeavor to reach wider markets. Compliance to global standards also ensures efficiency in transactions, product quality, and safety, resulting in total customer satisfaction. This blog intends to dissect the elements of the import process, emphasizing critical considerations that should guide professionals dealing with packaging machinery in ensuring that importation meets the respective international standards.

Identifying Key Global Standards for Packaging Machinery Imports

In the case of importation packaging machinery, understand that worldwide standards must be followed along with compliance for effective operation. By knowing important world regulations, companies can save themselves from unnecessary expense from delays and penalties and ensure the safety and reliability of their equipment. This blog will detail some of the most vital standards importers need to put into mind while importing packaging machinery to their countries. ISO 9001 certification is one of the most widely known standardizations; it has to do with quality management systems. This means that the manufacturer stands to ensure that the customer and regulatory requirements are kept, thereby creating satisfaction in its customers. Therefore, importers need to check that the packaging machinery they want meets this standard: it guarantees a commitment towards quality and continuous improvement. One of the most important standards belongs to CE marking in Europe. This is used to manifest that the machine meets the health, safety and environmental protection standards established by or under the European directives. Importers shall make certain that their equipment completed their assessments under the Machinery Directive (2006/42/CE). Besides, it is essential to comprehend specific industry regulations, such as FDA regulations for food packaging machinery in the United States, since all this is meant to avoid interference with import processes. Speaking about environmental standards, WEEE (Waste Electrical and Electronic Equipment) and RoHS (Restriction of Hazardous Substances) are becoming more and more relevant with global trading. Compliance with these environmental regulations definitely gives a green signal to business operation across nations, and it becomes a positive sign for many consumers who are becoming increasingly eco-sensitive. As the importation of packaging machinery is increasing day by day, it will be very critical to recognize and comply with these international standards for successful entry and continued operations.

Exploring Regulatory Requirements by Region: North America, Europe, Asia

Global standards for importation of packaging machinery are influenced by very different regulatory regimes in different regions, especially North America, Europe, and Asia. Each of these regions has its own set of requirements, which can have drastically different implications for small and medium enterprises (SMEs) as opposed to big corporations. SMEs face challenges in their operations since they have fewer resources and less expertise in dealing with international regulations. On the other hand, large enterprises have the financial muscle to adjust to the wide scope of regulations and quickly respond to opportunities in different markets.

Adding to these considerations are the end-users in this industry, which also include banking institutions such as banks, insurance companies, NBFCs, and credit cooperatives. These organizations incentivize the demand for risk management software that can incorporate the complicated regulatory environment and the risks therewith. For instance, a current process of revitalization in the financial services industry in Asia is as much as the evolution of such software to meet economic trends brought on course by the pandemic. The adaptation and evolution of these products to meet contemporary business and regulatory settings are an absolute necessity.

Otherwise, as regulations are changing, there will be a greater demand seen in the regions for sophisticated tools that do their work with risk assessment. The changes would require companies to be prepared and respond appropriately with their strategies to changing regulatory frameworks. While this helps them remain compliant, it puts them in a vital position to be competitive in the international market. With the right technology, companies will be capable of carving out an advantageous position to meet the requirements of regulators and clients, henceforth ensuring increasingly sustainable growth amid evolving environments.

Understanding Industry Certifications: ISO, CE Marking, and Others

There are various types of industry certifications pertaining to packing machinery, all aimed at achieving standards of compliance and safety. Among other globally accepted certifications, ISO (International Organization for Standardization) and CE marking stay ahead of the rest. In essence, the ISO certification is recognition that a company follows international standards with respect to quality management, environmental management, and such operational practices. This or any international equivalence will invariably build confidence among consumers regarding product quality and is, therefore, an important certification for a company that aspires to enter the global market.

As for the CE marking, it is a declaration by the manufacturer that their product fulfills the basic requirements of the applicable EU directives and regulations. It is essential for the placement of machines since it confirms the safety of the equipment and evaluation methods applicable. If the machinery is CE-marked, import to the EU would ensure compliance with the specific regulations, thus facilitating easier access into the European markets. The certification will also involve stringent tests and documentation required to prove conformity, thereby making it critical to meet the standards to avert possible legal problems.

Apart from ISO and CE marking, many other certifications may apply, depending on the intended market for the machinery. UL certification is extremely important for machinery being sold on the North American market, applying to equipment safety and reliability. It is imperative to understand the specific requirements in the target market and ensure that the particular machinery meets all the necessary certifications to be confidently entered in the highly regulated field of packaging machinery importation.

Navigating Compliance Documentation and Testing Procedures

The procedure for importing packaging machinery into a various country is a bewildering and boring affair because of the grueling endorsement documentation and testing process. Basically, they must understand the worldwide standards because it has been improving with international regulations over time. The document gives stepwise guidance to companies on how their machines will be able to meet the compliance requirements.

This would entail firstly understanding the relevant regulations as far as the specific target market is concerned. Every other country usually has distinct safety standards and environmental considerations at a place with technological requirements regarding packaging machinery. But the documentation has to be right, usually involving technical specifications, safety analysis reports, and recognized authorities' certification of compliance. Local expertise or consultancy would give the companies invaluable inputs regarding the technicalities within the environment.

Last, after documentation is done, testing procedures would follow to state that those machines follow the standards. There is also a possible inclusion of independent testing labs where they can test performances and safety. This last step provides compliance and certainly increases public confidence in the quality of one's goods as regulations vary over time and demand constant monitoring and adjustment.

Insights on Market Trends: Growth Projections for Packaging Machinery Imports

The global packaging machinery market enjoys massive growth due to increasing consumer awareness levels and an ongoing demand for sustainable solutions; industries are changing with new market trends such as the greater focus on eco-friendly packaging. Thus, import operations for packaging machinery are expected to increase tremendously. Market research says that imports of packaging machinery will thus play an important role in meeting the changing needs of various sectors by 2025.

The Southeast Asian situation highlights Indonesia even further. Industrial machinery demand, including packaging equipment, is exponentially growing in a country of around 300 million people with a constant GDP growth rate above 5%. Many local industries are poorly equipped and hence rely heavily upon imports; therefore, this trend offers great opportunities for international suppliers to venture into this fast-growing market.

Along with technology manure and efficiency lies in this field; thus, businesses better keep themselves posted about the latest innovations in the realm of packaging machinery. Adaptiveness to these trends will be the real key for companies aiming to penetrate others or expand their footprint in disseminated markets all over the world. In the end, sustainability momentum and growth in emerging markets make it imperative for communicating global standards and aligning import strategies accordingly.